Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xImprove tool management efficiency. Manage tools throughout their entire life cycle.

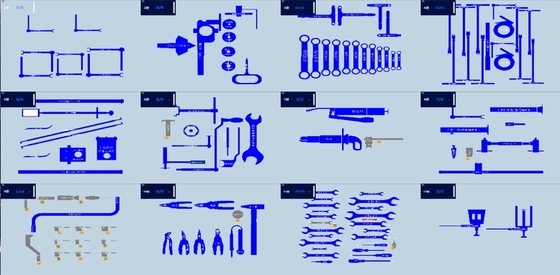

The random tool intelligent tool cabinet is mainly used to store common and special tools used in various professions during aircraft assembly and maintenance, and realize unmanned intelligent management of tool borrowing and returning. At the same time, it can be conveniently moved at any time as needed to meet the needs of on-site fixed placement and standardized management.

- Efficiency

Significantly improves tool collection and return speed, eliminating manual registration and enabling quick inventory management of inventory and loaned tools. - Security

Tiered management of tool user and administrator permissions, with multi-login via facial recognition, fingerprint, and password. - Intelligent

Automatically identifies and records tool collection and return, providing overdue returns and reminders of scheduled inspections. - Informatization

Supports user and tool usage frequency analysis and big data management of tool lifecycles.

- Indirectly manages tools and suffers from poor confidentiality

- Signal leaks have caused customers to discontinue use

- Requires changing tool form and adding tags of different sizes

- Tool tags must be sealed and regularly inspected

- Reading speed and accuracy affected by antenna signal and tag performance

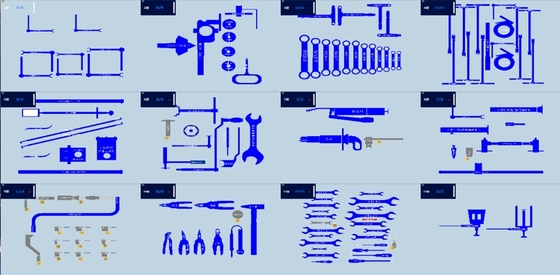

- Directly manages tools without affecting their integrity

- Tool color or weight irrelevant to functionality

- No need to alter tools through gluing or inlaying

- Fast and accurate reading speed

- Highly sensitive to light with rapid resistance changes

- Operator authentication via face and fingerprint recognition

- Automatic recognition of tool type and quantity

- Comprehensive operation recording and reporting

- Return reminders and scheduled inspection notifications

- Tool lifecycle management and usage frequency analysis

- Integration capability with existing production management systems